#SafetyFirst: Absence of Voltage Testing Keeps You Alive and Protected

Worldwide statistics show that electrical workers suffer the highest number of electrocutions per year and that human interaction accounts for the leading cause of system outages, compromising a facilities operational reliability. The Electrical Safety Foundation International (ESFI) statistical data reports that contact to electrical current accounted for 2.6% of all fatalities in 2020 of which 5.39% were fatal, with the mining industry reporting the highest rate of fatal electrical injuries followed by construction. Safety therefore remains the first tool to use when working within an electrical environment and industry fatalities are a strong reminder for decision-makers to allocate safety resources for maximum impact.

Enabling and maintaining a process-orientated safety approach or method of procedure (MOP) manages the process of reaching a deenergized state before any electrical work can take place.

Performing absence of voltage testing is mandatory on all electrical work and electrical circuits where testing takes place on each phase conductor or circuit part, both phase-to-phase and phase-to-ground, making it the most vital step in the process of verifying and establishing a deenergized state of any electrical system.

What is a true deenergized state? It is when the energized parts have been disconnected from energized parts, locked or tagged in line with established standards and tested to ensure there is an absence of voltage, and it is grounded if further required. It is only then that you may perform work on electrical equipment, secure in the understanding and confirmation of your personal safety and the knowledge that there will be no additional damage to equipment.

While absence of voltage testing establishes a deenergized state when working on energized electrical tasks, the responsibility remains on you, the electrical practitioner, to ensure electrically safe working conditions and the correct use of testing instrumentation to ensure lives and the protection of site equipment from start to finish.

Absence of voltage testing requires the following steps:

#1 You are using the best tool for the job when identifying, testing and measuring live electrical circuits.

#2 Your volt test devices are verified as operating properly before and after verifying the absence of voltage on a known voltage source.

#3 You understand the measurement categories and the method of classification of potential energy available at any point within a circuit. This includes the potential for transient voltages that can spike voltages beyond normal levels, such as lighting strikes, and arching.

Measurement Categories

When testing for absence of voltage, the measurement categories are divided into 4 CAT ratings and understanding what each of these category’s means is essential to choosing the correct equipment for the work at hand to avoid exposure to risk, whether you are intending to use a basic multi-meter in a home or office environment or an industrial testing device when inspecting large power infrastructures.

It is essential that the electrical tool carries the correct CAT rating for the electrical application and a voltage rating higher than the maximum voltage of the environment in order to withstand dangerous surges in voltage.

Selecting the Right Tool for the Job

For 600 volt and less electrical systems, Category (CAT) I through to CAT IV test instrumentation are used to rate test instruments on their ability to resist a voltage spike, which is applied through a specific resistance.

CAT I absence of voltage testers should only be used on secondary circuits not intended for connection to mains electricity supply. These include distribution wiring and branch circuits with permanently installed loads such as electronic equipment, televisions, computers and monitors, as these measure voltages from specially protected secondary circuits where voltage measurements include signal levels, limited energy parts and circuits powered by low-voltage sources.

CAT II test instruments are for local-level electrical distribution and should only be used on appliances, portable tools, outlets and branch circuits which use local-level electrical distribution such as a standard mains socket and plug-in and single-phase loads. Test instrumentation for CAT I and CAT II include digital multi-meters (DMM) for measuring voltage, current and resistance and they can check battery voltages, vehicle electrics, continuity of cables and power cords and fuses, allowing you to measure DC voltage, DC current, AC voltage, AC current, resistance and continuity.

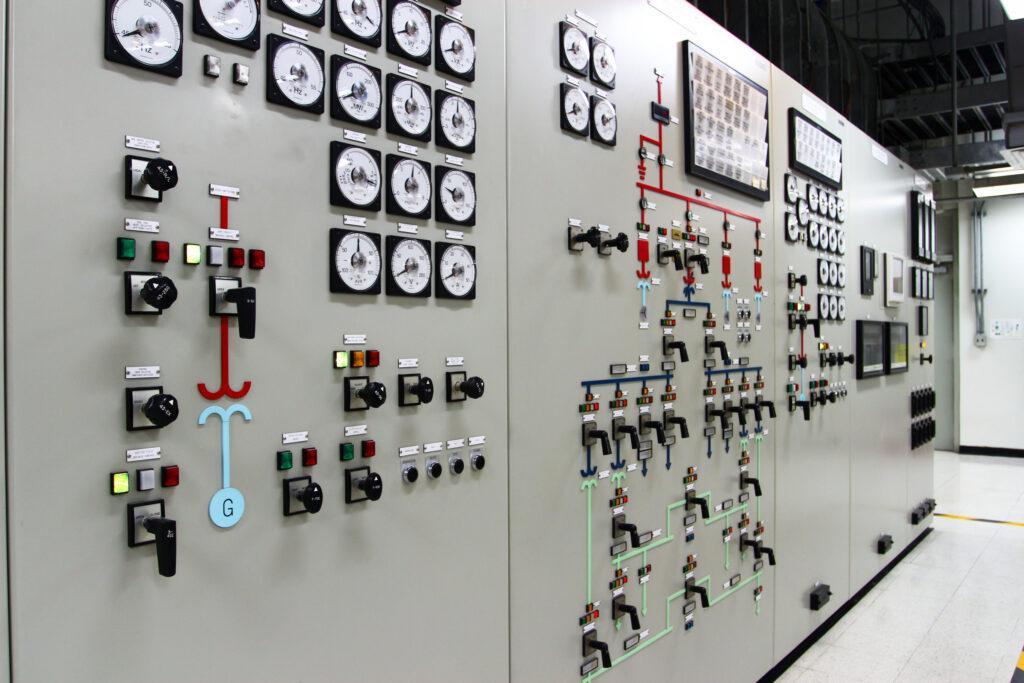

CAT III test instruments are for 3-phase distribution and are used in commercial and industrial settings for electrical installations, distribution wiring, including main busses, feeders, and branch circuits with permanently installed loads in buildings and industrial equipment.

CAT IV test devices are for ‘origin of installation’ measurements on hard-wired equipment, circuit breakers, distribution boards, stationary motors with permanent connections to fixed installations at origin, and at power grid infrastructure connection level. Absence of voltage testing used in these scenarios, determines if a circuit part is de-energized before opening panels or removing electrical box covers to access and work on the electrical equipment. The recommended testing instrumentation for the job at this level is a high voltage noncontact proximity detector, where physical contact with electrical conductors is not necessary when testing for live lines. Here, the instrumentation sensor senses the radiated field which surrounds live conductors. Radiated field strength will increase with voltage and it will decrease with distance or earth shielding. A noncontact proximity detector identifies and checks live cables, finds fault in flexible cables, checks earth equipment, services neon lightning, traces live wires, checks high frequency radiation, and detects residual or induced voltages.

All test instrumentation from multi-meters to electrical testers and non-contact proximity detectors must comply to approved test instrument ratings and carry a calibration certificate (usually valid for a year) by an approved supplier which maintains the accuracy of the instrument to an acceptable level, usually within 2% of the true value. If test instrumentation is not properly maintained, it can lead to shock risks.

CAT Safety with Ohm’s Law

Do not make the error of simply matching the presumed voltage to the test and measurement device. This is because failed electrical units can produce impulse or transient voltages many times above an electrical tool’s rating which can cause a short circuit and arcing which can severely injure personnel.

When doing absence of voltage testing, CAT 1 testing equipment should never be used for performing tests on Category II and above. It is recommended to use the working versus transient voltage chart guidelines (below) for each CAT rating supplied by the International Electrotechnical Commission (IEC), using Ohm’s Law, to get the accurate current in each example. As you will see in the highlighted sections that even though two CAT ratings cover the same working voltage, it does not mean they are an equal. Using CAT III at 600V and CAT II at 1000V clearly displays that just because the rated working voltage is higher, it does not mean that it can handle as much load overall.

| Measurement Category | Working Voltage | Transient Voltage | Test Source (Impedance) | Working Current | Transient Current |

| CAT I | 150V | 800V | 30 Ohms | 5A | 26.6A |

| CAT I | 300V | 1500V | 30 Ohms | 10A | 50A |

| CAT I | 600V | 2500V | 30 Ohms | 20A | 83.3A |

| CAT I | 1000V | 4000V | 30 Ohms | 33.3A | 133.3A |

| CAT II | 150V | 1500V | 12 Ohms | 12.5A | 125A |

| CAT II | 300V | 2500V | 12 Ohms | 25A | 208.3A |

| CAT II | 600V | 4000V | 12 Ohms | 50A | 333.3A |

| CAT II | 1000V | 6000V | 12 Ohms | 83.3A | 500A |

| CAT III | 150V | 2500V | 2 Ohms | 75A | 1250A |

| CAT III | 300V | 4000V | 2 Ohms | 150A | 2000A |

| CAT III | 600V | 6000V | 2 Ohms | 300A | 3000A |

| CAT III | 1000V | 8000V | 2 Ohms | 500A | 4000A |

| CAT IV | 150V | 4000V | 2 Ohms | 75A | 2000A |

| CAT IV | 300V | 6000V | 2 Ohms | 150A | 3000A |

| CAT IV | 600V | 8000V | 2 Ohms | 300A | 4000A |

| CAT IV | 1000V | 12000V | 2 Ohms | 500A | 6000A |

It is recommended electricians carry an electrical multi-meter that gives CAT III protection at 1000 volts, and Category IV protection at 600 volts and to be cognisant to wear Personal Protection Equipment (PPE) to include safety glasses, face shields, hard hats, safety shoes, insulating rubber gloves with leather protectors, insulating sleeves, and flame-resistant clothing. PPE must carry the maximum Arc Rating which is the maximum incident energy resistance demonstrated by a material prior to its energy break open threshold (EBT) and probability for second- or third-degree burn.

The adage, ‘when in doubt, do nothing’ applies here. If you do not have the right testing tool for the job or do not know how to perform the test or are unclear regarding the correct equipment, category and volt class, it is essential you step back and seek advice from a more experienced electrician or understand the safety and support benefits of a full-service testing company.

Ask our team of experienced and electrically licensed Service Engineers, trained specifically in Critical Power System standard, applications and design, when looking for high quality results in service and maintenance of today’s Critical Environments. Contact us now