Electrical Protective Gear Saves Lives from the Ground Up

Statistics tell us that for every 100,000 electricians there are ten fatalities on the job with all electrical shocks falling into two categories, either unsafe conditions or unsafe acts. It highlights that the role of the electrician comes with both high risk and high responsibility. Protective electrical-work safety gear can ensure you don’t become a statistic.

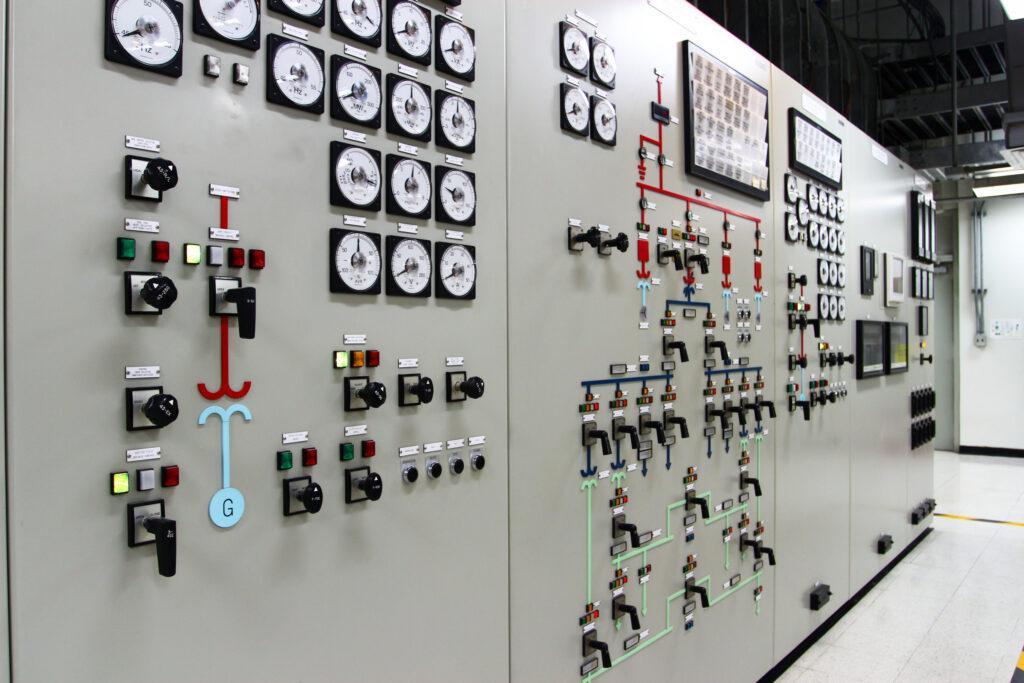

Reputable electrical companies understand the risk and precautions required for working on or near high voltage electric power, generation, transmission, and distribution equipment where specialised clothing and equipment for specific voltage tasks can avoid permanent injury or death. Every electrician or technician in an industrial environment, needs to understand how electricity is generated, distributed, used, and controlled and how to protect themselves whilst on the job.

As one of the most important forms of energy, electricity powers much of industry and production today, and just like lightening in nature, electricity is a natural force produced by the movement of positive and negative electrons. Its unpredictable nature however means that each environment and every situation have specific procedures for assessing the risk and how to engage when working with electrical force.

Electricity can jump and an arc blast can produce an explosion with temperatures up to six times the surface of the sun, while the bite of a sustained electrical current can create shock, injury, concussion, and death. Some of the most dangerous environments for electricians is live work on high voltage circuits, and tasks within non-electrical industrial hazards. This can mean working in trenches or high in the air, requiring technicians to carry heavy equipment in unsafe environments, enduriing very high or very low temperatures and industrial noise all day while having to sustain awkward and uncomfortable positions – all the while remaining mentally agile, alert and alive on the job.

Electrical current becomes fatal for humans at values as low as 20 milliamps, where breathing becomes difficult, with life coming to an end at values below 75 milliamps. As the current reaches 100 milliamps, ventricular fibrillation of the heart occurs producing uncoordinated twitching of the walls of the heart’s ventricles which results in death. Fatal situations can be prevented when the correct PPE is used as a layer of protection against accidents and mishaps when working within electrical environments.

Let’s take a look at the standard protocols for protective gear from the ground up.

Anti-static footwear prevents the build-up of static electricity from walking and the movement of your body in static-sensitive environments while still providing a level of resistance to electrical hazards from live circuits. This type of boot should carry insignia declaring it ESD (electrostatic discharge) or SD (static discharge) safe for assurance of reduced risk of ignition from a static electric spark.

Non-conductive footwear (carrying the EH marking) denotes non-conductive rated shoes which are designed to reduce the flow of electricity through your body to protect you from the possibility of being accidently electrocuted.

All protective footwear, to be worn at all times, should feature steel toe caps enclosed by non-conductive materials (such as rubber, leather or insulation), making them safe to wear in live circuit environments, have non-skid rubber soles and have an impact resistance rating of 75 and a compression rating of 75. Long-wearing, quality footwear should be water and abrasion-resistant to protect electricians against ground charges, chemical spills, injury from heavy objects colliding with the feet and slips and falls.

The correct fit of the shoe is imperative. For the best fit when buying new shoes, shop for boots end of the day when your feet have been working hard and are most enlarged. Take along a thick pair of socks when fitting work boots correctly. Add additional comfort throughout the long workday with cushioned insoles and good laces that do not fray. Shoes, as with all protective work gear should be well maintained and properly stored when not being used.

SAFETY PRECAUTION #1

Rubber gloves and rubber shoes will not protect you from electrical shock if there is a tear or a hole in them.

PPE Gear

Arc flash resistant clothing is made from lightweight fabrics which are breathable yet meet or exceed international standards for protection and performance. If PPE does not fit properly, it can make the difference between being safely covered or dangerously exposed according to OSHA, the USA based Occupational Safety & Health Administration. OSHA, NESC (National Electrical Safety Code and NFPA (National Fire Protection Association) mandate the use of arc resistant and fire-resistant clothing for safe electrical workplace practices.

The Arc Rating for PPE is the maximum incident energy resistance demonstrated by a material prior to break open or necessary to pass through and cause with 50% probability a second- or third-degree burn.

Arc Rating is normally expressed in cal/cm² (or small calories of heat energy per square centimetre). National Fire Protection Association (NFPA) defines Arc Flash safety regulations for OSHA compliance.

It is essential that all electrical technicians and electrical companies check the labels and Arc Ratings on any garments that are purchased to ensure they comply with the legislated industry standards and can protect against arc flash risks and hazards.

Hi-Visibility Flame Resistant Workwear

Visibility on the job is important and flame-resistant workwear reduces the chance of being struck by hazards and protects against burn injuries cause by arc flash accidents. However, even flame-resistant garments can break open due to the extreme energy force and it is advised electrical technicians wear loose-fitting flame resistant inner layers, with a protective clothing outer layer, and underwear that won’t melt. Under-layers made with synthetics, such as nylon and polyester, will burn in contact with intense heat.

Arc rated protective gear includes:

- long-sleeve shirt and pants or arc-rated coveralls

- arc-rated face shield or arc flash suit hood

- arc- rated jacket, parka, rainwear, and arc-rated hard hat liner

- arc-rated face shields and safety glasses

- hard hats with high-voltage shock and burn protection up to 20,000 volts

- hearing protection or ear canal inserts

- voltage rated gloves with leather protectors.

The Best practices require electrical companies to replace PPE every five years.

SAFETY PRECAUTION #2

Work with proper lighting. Electrical apparatus is not always housed within well-lit environments. Ensure you have sufficient light to work safely so you are not reaching into dark spaces which might contain energised parts. A head lamp and powerful rechargeable solar lamp should be part of your safety equipment.

Our team at Praetorian Power consists of experienced and electrically licensed Service Engineers who have been trained specifically in Critical Power System standard, applications and design in order to deliver premium services with precision and with the highest regard for Safety. Find out more about our services and offerings on our [Services] page